Türkiye’s defense industry is set to play a key role in boosting Germany's 155mm artillery ammunition production capacity through a new technology transfer agreement.

Repkon, a leading Turkish defense company, has signed a contract with one of Germany’s foremost ammunition manufacturers to establish a turnkey facility for the filling of 155mm artillery shells with explosives.

The facility, expected to be operational in early 2027, will not only handle traditional ammunition but also incorporate modern, high-explosive next-generation munitions, enhancing Germany's supply security in this sector.

The demand for artillery shells has surged globally, particularly in the wake of the Russia-Ukraine war. Many countries are now investing in expanding their production capabilities to meet growing military requirements.

Germany, in particular, is ramping up its defense production due to its expanding security needs, military aid to Ukraine, and commitments within NATO. One of the major strategic goals for Germany is to increase the production of 155mm artillery ammunition.

Repkon has become a preferred partner for countries seeking to expand their ammunition production capabilities. The company has previously signed agreements to establish similar ammunition production facilities in the United States, Pakistan, and Azerbaijan.

With the latest deal, Germany has now joined the list of nations collaborating with the Turkish defense industry for artillery shell production.

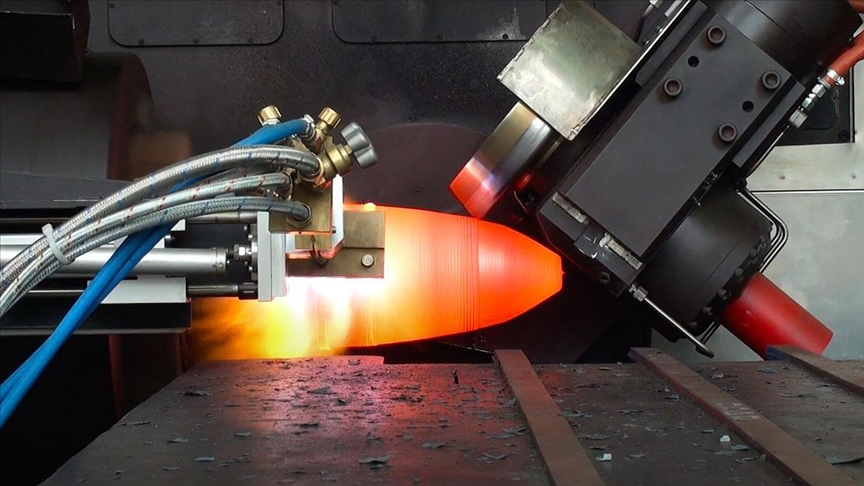

Under the newly signed agreement, Repkon will build and deliver a state-of-the-art explosive filling facility for 155mm artillery shells in Germany.

This turnkey project will introduce an advanced production line that emphasizes automation and minimizes human labor involvement, making it one of the most technologically sophisticated facilities of its kind worldwide.

Germany aims to strengthen its domestic manufacturing capacity and ensure a secure supply chain for its artillery ammunition needs through this investment.

The contract also includes provisions for a significant procurement order of 155mm artillery shells.

Repkon is recognized as one of the few companies globally with the expertise to establish explosive filling facilities. To further enhance its capabilities and meet rising demand, the Turkish defense firm recently acquired Bowas, a company operating in Austria, Italy, and Switzerland that specializes in the design and production of equipment for the explosive materials and raw materials industry.

Bowas' experience in both military and civilian explosives, as well as munitions disposal, has significantly bolstered Repkon’s ability to meet the increasing global demand for artillery ammunition.

This acquisition enables Repkon to offer a complete production solution, covering metal shell manufacturing, explosive filling, and explosive production facilities—making it the only company in the world capable of delivering all three components as a single integrated solution.